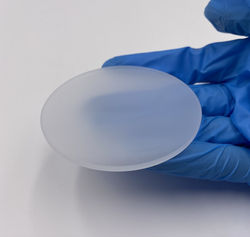

SPUTTERING TARGETS (check out the images below)

We supply a wide variety of sputtering targets, whether ceramic, metallic or alloy. Targets are produced using the most advanced manufacturing techniques, such as vacuum hot pressing, hot or cold isostatic pressing and vacuum casting. Depending on the type of material, our team evaluates the most appropriate technique to be used.

The purity of the products is ensured through the Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) technique, which evaluates the amount of metallic and non-metallic impurities present in the samples.

According to our production capacity, we can supply targets with the following characteristics:

-

Purity: 99.9% (3N) - 99.9999% (6N)

-

Round shape: standard diameters from 1" to 8" (above 8" are also possible)

-

Rectangular shape: available in different dimensions

-

Thicknesses: different thicknesses are possible*

-

Bonded to oxygen-free high conductivity copper bases (OFHC backing plates)**

* Very thin thicknesses make the manufacturing process difficult

** Normally ceramic targets are fragile and have low thermal conductivity. Therefore, we strongly recommend the process of gluing these targets onto copper bases, in order to avoid cracks due to thermal shock and/or the installation process. We offer this gluing service using metallic indium or elastomer as glue. We have oxygen-free copper (OFHC) bases

See below a list of the main types of targets we can provide (other targets can be requested):

1) METALS

Al, B, Bi, C, Cd, Cr, Co, Cu, Fe, Ge, Hf, In, Ir, Mg, Mn, Mo, Nb, Ni, Pd, Re, Ru, Sb, Se, Si, Sn, Ta, Tb, Ti, Tm, W, V, Zn, Zr

2) PRECIOUS METALS

Ag, Au, Pt

3) RARE EARTH

Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu

4) ALLOYS

AlCu, AlCr, AlMg, AlSi, AlSiCu, AlAg, AlV, CaNiCrFe, CaNiCrFeMoMn, CeGd, CeSm, CrSi, CoCr, CoCrMo, CoFe, CoFeB, CoNi, CoNiCr, CoPt, CoNbZr, CoTaZr, CoZ r, CrV, CrB, CrSi, CrCu, CuCo, CuGa, CuIn, CuNi, CoNiPt, CuZr, DyFe, DyFeCo, FeB, FeC, FeMn, GaAs, GdFe, GdFeCo, HfFe, InAs, InSn, IrMn, IrRe, MoSi, NiAl, NiCr, NiCrSi, Co, NiFe, NiMn, NiNbTi, NiTi, NiV, SmCo, AgCu, AgSn, TaAl, TbDyFe, TbFe, TbFeCo, TbGdFeCo, TiAl, TiNi, TiCr, WRe, WTi, WCu, ZrAl, ZrCu, ZrFe, ZrNb, ZrTi, ZrY, ZnAl, ZnMg

5) BORIDES

Cr2B, CrB, CrB2, Cr5B3, FeB, HfB2, LaB6, Mo2B, Mo2B5, NbB, NbB2, TaB, TaB2, TiB2, W2B, WB, VB, VB2, ZrB2

6) CARBIDES

B4C, Cr3C2, HfC, Mo2C, NbC, SiC, TaC, TiC, WC, W2C, VC, ZrC

7) FLUORIDES

AlF3, BaF3, CdF2, CaF2, CeF3, DyF3, ErF3, HfF4, KF, LaF3, PbF2, LiF, PrF3, MgF2, NdF3, ReF3, SmF3, NaF, Na3AlF6, SrF2, ThF4, YF3, YbF3

8) NITRIDES

AlN, BN, GaN, HfN, NbN, Si3N4, TaN, TiN, VN, ZrN

9) OXIDES

Al2O3, Sb2O3, ATO, BaTiO3, Bi2O3, CeO2, CuO, Cr2O3, Dy2O3, Er2O3, Eu2O3, Gd2O3, Ga2O3, GeO2, HfO2, Ho2O3, In2O3, ITO, Fe2O3, Fe3O4, La2O3, TiO3, PbZrO3, LiNbO3, Lu3Fe5O12, Lu2O3, MgO, MoO3, Nd2O3, Pr6O11, Pr2O3, Sm2O3, Sc2O3, SiO2, SiO, SrTiO3, SrZrO3, Ta2O5, Tb4O7, TeO2, ThO2, Tm2O3, TiO, TiO2, TiO2:Pr, Ti3 O5, Ti2O3, SnO2, SnO, WO3, V2O5, YAG, Y3Al5O12, Yb2O3, Y2O3, ZnO, ZnO:Al, ZrO2 (stabilized)

10) SELENATES

Bi2Se3, CdSe, In2Se3, PbSe, MoSe2, NbSe2, TaSe2, WSe2, ZnSe

11) SILICATES

Cr3Si, CrSi2, CoSi2, HfSi2, MoSi2, NbSi2, TaSi2, Ta5Si3, TiSi2, Ti5Si3, WSi2, V3Si, VSi2, ZrSi2

12) SULFIDES

Sb2S3, As2S3, CdS, FeS, PbS, MoS2, NbS2, TaS2, WS2, ZnS

13) TELLURIDES

CdTe, PbTe, MoTe2, NbTe2, TaTe2, WTe2, ZnTe

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |  |

|  |  |

|  |